General Information about sealing surfaces

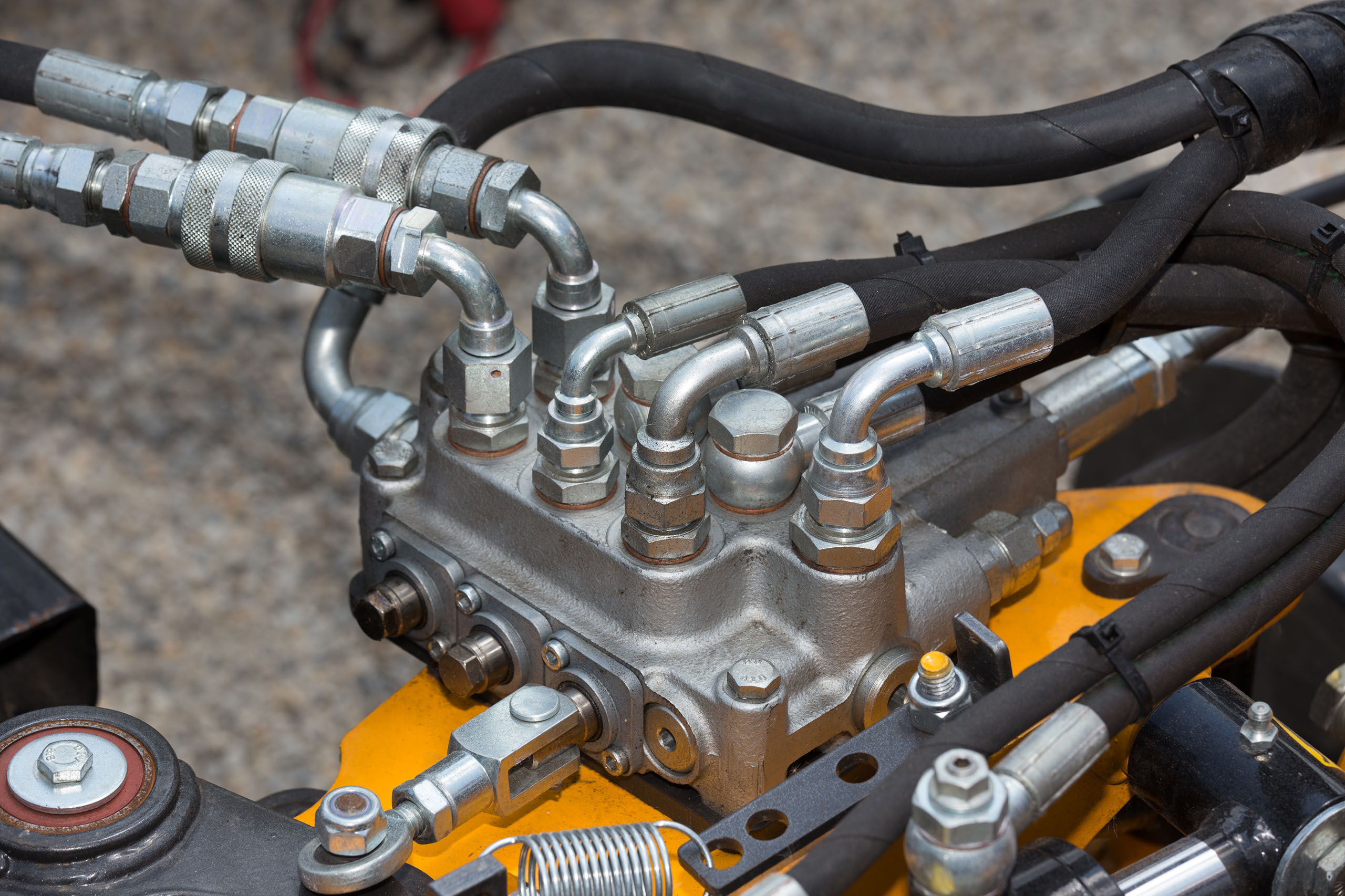

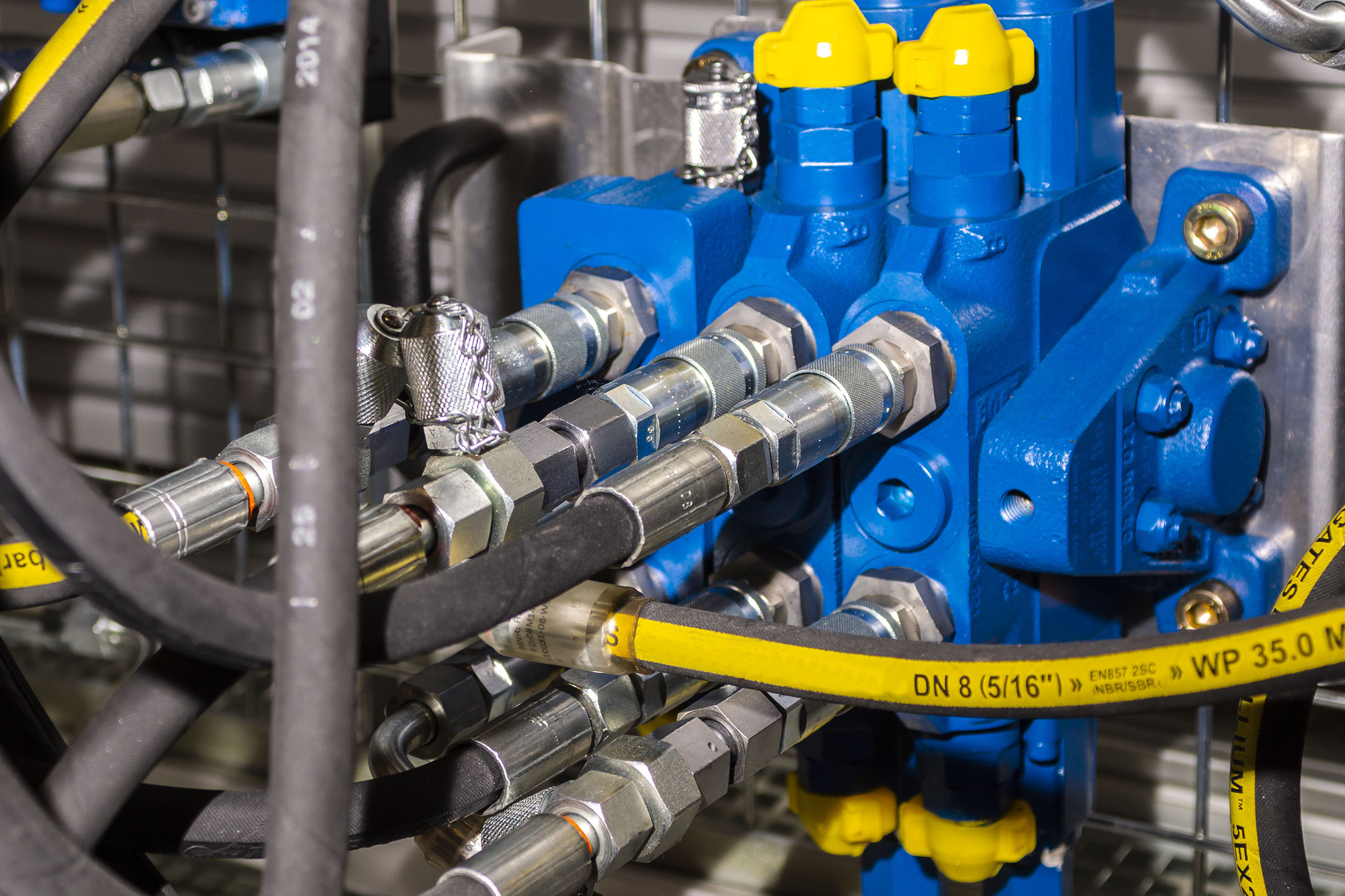

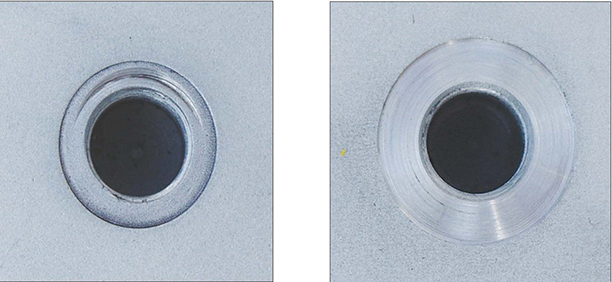

Sealing surface quality on screw-in bores ISO 1179-1 / DIN 3852-2; ISO 9974-1 / DIN 3852-1 (Fig.1) is decisive for the functional safety of hydraulic systems, machines or installations.

Improperly manufactured or damaged sealing surfaces (Fig. 2) leak and are therefore an immediate cause for system breakdowns.

For this reason, the entire fluid technology field puts special emphasis on the high-quality design of sealing surfaces.

The essential evaluation criteria for a sealing surface are:

1. Positional deviation (angular position) of the sealing surface with respect to the screw-in bore thread

2. The surface finish of the sealing surface

When producing hydraulic components in series using machine tools (as is the case in a machining center, a boring mill and a milling or drilling machine, for instance), the 1st criterion is generally fulfilled by the machine's condition.

If the machine’s condition is very good, fulfillment of the 2nd criterion does not depend on the machine but on the tools. Unsuitable or dull tools produce surfaces that do not fulfill the 2nd criterion and cause functional problems that must be rectified when the components, machine groups or structural components are assembled, at the latest. When already operating structural components of systems, machines or installations are repaired, screwed pipes or locking screws must generally be disassembled, so that during assembly the corresponding sealing surfaces on the screw-in bores do not fulfill the 2nd criterion most of the time. Sometimes, the surfaces are damaged, corroded or colored.

Damages can occur either by using threaded pipes or locking screws with metallic sealing edges or by careless disassembly. Therefore, a refinishing or repairing of the sealing surface is essential so that the functional safety of the repaired hydraulic system, machine or installation is ensured once again after assembly.

Without multicut*-precision tools, the refinishing of damaged sealing areas needs the use of expensive machine tools on which structural components must be laboriously aligned and processed.

In addition, the long waiting time plus the time needed for disassembling and reassembling the hydraulic systems causes production loss in the plants and machines. Often, the repair of only one sealing surface causes enormous expenses that often reach three or four figure

Contact:

REINHARD Feinmechanik GmbH

Assar-Gabrielsson-Str. 1

63128 Dietzenbach

Germany

Tel: +49 (0)6074 84127 0

Fax: +49 (0)6074 2020

info@reinhard-feinmechanik.de

Our offer is aimed only at business customers!

(B2B Shop)

Would you like to send a message?